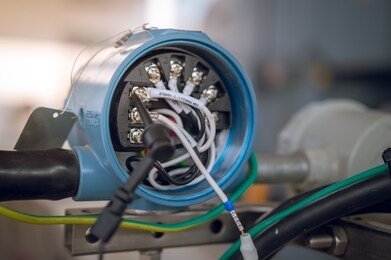

A temperature transmitter is a device that collects temperature data from a temperature sensor and sends it to a control system or display. It's like the messenger that carries the information from the sensor to where it's needed. These transmitters come in various forms, including analog, digital, and smart transmitters, each offering specific features and advantages.

Temperature transmitters are applied in various situations and industries so in this article, I'm going to introduce how temperature transmitters are applied.

The Significance of Temperature Sensors

Temperature sensors are the front-line troops, responsible for measuring the temperature in a given environment. They come in various types, such as thermocouples, RTDs (Resistance Temperature Detectors), thermistors, and infrared sensors.

The type of sensor you choose depends on the specific requirements of your industrial process. For example, thermocouples are known for their versatility and can handle extreme temperature ranges, making them suitable for a wide range of applications.

How a Temperature Transmitter Works

Temperature transmitters take the electrical signals generated by these sensors and convert them into a standardized output, typically a 4-20mA signal. This signal can be easily interpreted by control systems, programmable logic controllers (PLCs), or distributed control systems (DCS). The transmitter ensures that the signal accurately represents the temperature reading from the sensor.

Calibrating for Accuracy

To ensure your temperature control system is accurate, regular calibration of both the transmitter and sensor is crucial. Calibration involves comparing the sensor's readings with a reference standard and making necessary adjustments. This process is essential for maintaining precise and reliable temperature control.

Advanced Features of Smart Transmitters

In recent years, smart transmitters have become increasingly popular. These transmitters not only send temperature data but also include advanced features like digital communication protocols (e.g., HART, Foundation Fieldbus, and Profibus). They enable two-way communication between the transmitter and the control system, allowing for remote configuration, diagnostics, and more.

Ensuring Safety and Compliance

In some industries, such as chemical processing, temperature control is not just about product quality but also safety. Maintaining temperature within safe limits is essential to prevent accidents. Redundancy and safety measures, such as emergency shutdown systems, are common in these scenarios.

Energy Efficiency and Sustainability

Temperature control is also closely linked to energy efficiency. In many industries, heating or cooling processes can consume a significant amount of energy. Optimizing temperature control systems can lead to substantial energy savings, contributing to sustainability efforts and reducing operational costs.

The Role of Automation

Automation has revolutionized temperature control in many industries. Modern control systems can be programmed to maintain specific temperature setpoints, initiate alarms when conditions deviate from the norm, and make real-time adjustments to heating or cooling systems. This level of automation ensures consistent and efficient temperature control.

Conclusion

Applying temperature transmitters in industry is a crucial part of maintaining the quality, safety, and efficiency of various processes. By selecting the right sensors, ensuring calibration, leveraging advanced features of smart transmitters, and focusing on safety and energy efficiency, industries can optimize their temperature control systems. The future promises even more advancements in this field, making temperature control an exciting aspect of industrial processes. If you are looking for any related products, please contact us!