IC Chips: The Ultimate FAQ Guide

1. What is IC Chips?

IC chips are sets of electronic circuits on a small flat silicon semiconductor material or a chip.

It is a semiconductor wafer with millions of tiny capacitors, transistors, and resistors.

Integration of a higher number of minute MOS transistors into smaller chips results in faster and less expensive devices.

2. What do IC Chips do?

You can use IC chips for different functions depending on the applications such as:

- Timer as it is in integral device in digital watches

- Oscillator

- Amplifier

- Counter

- Computer memory being an integral device in the RAM and ROM drives.

- Microprocessors

IC ChipsIC Chips

3. What is Inside IC Chips?

IC chips consist of millions of different components that assist in the normal function of the IC chip.

The main components of the IC chips include:

- Resistors that control the flow of current to other components on the device.

- Capacitors which are used in the storage of electrostatic energy in electric fields.

- Transistors which you can use in switching or amplifying electrical power and electronic signals.

- Semiconductor wafers such as silicon

- Copper which acts as the main electric conductor

4. How are IC Chips made?

In order to make an IC chip, you need to follow the following steps:

Step One: Preparation Stage

At this point you need to have the blue print of the IC chip that you intend to make ready.

You need to come up with a proper design which can either be standard or it can also be unique.

Standard designs are available for you to choose from different shelves such as amplifiers, and analog switches among others.

Unique designs will require research, development and extensive design work such coming up with new microprocessors for computers.

With the design at hand, you will need to find the raw materials for making the integrated circuit chips.

The main raw materials that you will need include:

- Pure silicon as the basis of most IC chips

- Aluminum which acts as the connector between different IC chip components.

- Mounting package which can either be plastic or ceramic among other materials.

You have to ensure that you are working in a clean room with filtered air, light frequencies and no foreign particles.

The operators within the clean room should also have gloves, lint-free garments, and covers for their feet and head.

Step Two: Actual Manufacturing Process

First you will make a single yet thin slice of silicon consisting of hundreds of integrated circuits.

After that you will cut the individual IC circuits apart thus making individual IC chips.

The manufacturing process begins with:

i. Preparation of Silicon Wafer

You will heat the silicon to melting point of about 1400 degrees Celsius inside a vacuum chamber.

Make sure that you avoid contamination by containing the heated region by surface tension which gets rid of impurities.

The impurities flow down to the base of the silicon which you will cut off completely and remain with pure silicon.

Using a wafer slicer, you will cut a thin round silicon wafer according to size specifications before polishing the surface.

Coat the layer of silicon wafer using silicon dioxide resulting in the formation of insulating base and prevent further oxidation.

ii. Masking

Using a computer aided drafting machine, you will prepare the design and then make the image into a mask.

After that you will optically reduce the mask and transfer it to the surface of the wafer.

The mask has cleat and opaque parts depending on the design with integrated images of all the components.

You will place a drop of photoresist material at the center of silicon wafer and spread it by spinning rapidly.

Bake the photoresist after spreading to remove the solvent before irradiating using short wave ultraviolet light.

Remove the mask and dissolve portions of the photoresist before chemically etching the areas that are still uncovered.

You can as well subject it to chemical doping in an attempt to create layers of P and N regions.

iii. Doping

You will then dope the device by either atomic diffusion or Ion implantation.

Doping involves the addition of a layer that will create P or N regions.

Atomic diffusion involves placing wafers in a quartz tube oven and heating to about 816 – 1205 degrees Celsius.

You will add the doping chemical on an inert gas which will deposit on the hot surface of the wafers without masks.

Ion implantation involves ionizing dopant gas to provide high energy dopant ions and then fired to specific regions.

The ions will go through the wafer and remain implanted.

Step Three: Making of Successive Layers

In this stage, you will repeat all the process in step two for every successive layer of the chips.

You might need to lay down a layer of silicon dioxide that will provide an insulator between the components.

You can achieve this through the process of chemical layer deposition before placing a final layer of silicon dioxide.

You will also perform final etching that will open up the contact points before depositing a layer of aluminum.

The layer of aluminum will make the contact pads after which you will test the individual layers for electrical functionality.

Step Four: Making Individual IC chips

In this case, you will separate the hundreds of individual chips by scoring cross hatches of line using fine diamond cutters.

After that, you will place the sheets under pressure and they will separate thus forming individual IC chips.

You will inspect the individual chips to remove any damaged chips as well as chips that fails the electrical test.

The good chips are bonded individually into mounting packages before connecting the thin wire leads by thermocompression or ultrasonic bonding.

You will then mark the chips using identity marks such as part numbers as well as other information.

Step Five: Final Packaging

After the final testing you will package the IC chips in a hard plastic package.

This is the part that you will see when you look at the motherboard of a computer or any device with IC chips.

The package has connection pins that connect the IC chips to the printed circuit board.

After that, the integrated circuit chip will be ready for shipping.

Integrated circuit chips

5. How many Types of IC Chips are there?

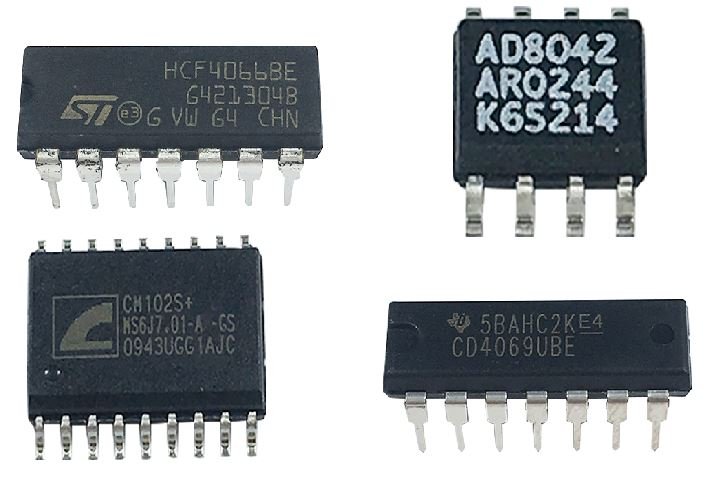

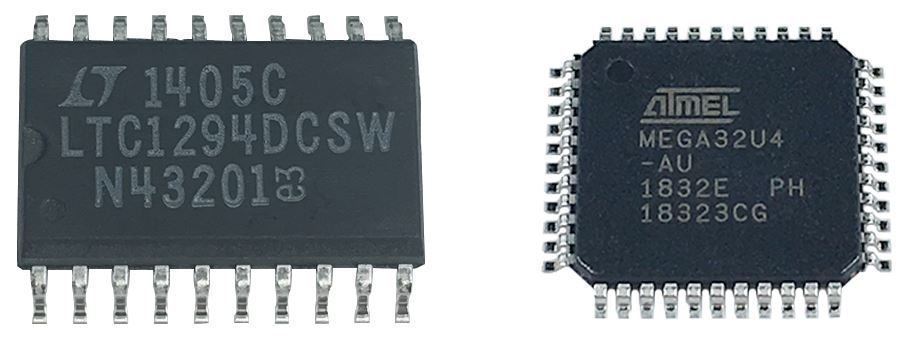

There are different types of IC chips available depending on the type of classification.

Classifications based on the intended application presents three main types including:

- Analog integrated circuit chips which operate over a continuous range of signals known as analog ICs.

This can either be linear IC chips or Radio Frequency IC chips

- Digital integrated circuit chips that operate at a few definite levels instead of all levels of signal amplitudes.

Apart from that, you may also come across another type of digital IC chip known as the logic circuit IC chip.

This type of IC chips has proper designs using logic gates that depend on binary outputs and inputs.

- Mixed integrated circuit chips which you can obtain by integrating digital as well as analog IC chips.

The chips function as converters from digital to analog and from analog to digital as well as clock timers.

You can also classify the IC chips based on number of components which are as follows:

- Small scale integration IC chips

- Medium scale integration IC chips

- Large scale integration IC chips

- Very large scale integration IC chips

- Ultra large scale integration IC chips

Other types of IC chip available include:

- Comparators IC chips

- Switching IC chips

- Audio Amplifier IC chips

- Operation Amplifier IC chips

- Timer IC chips

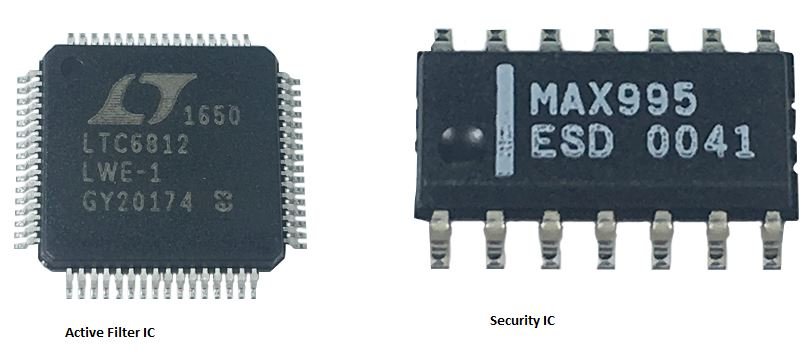

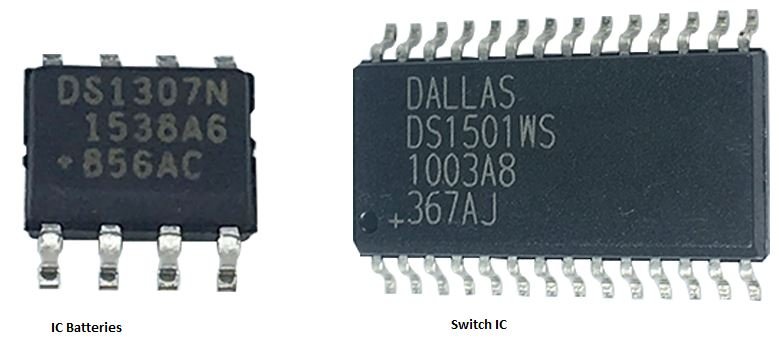

At Rantle East Electronic, we offer the following IC chips – counter IC, network IC, timer IC, active filter IC, multimedia IC, opto coupler IC, power management IC, security IC, switch IC, RF integrated circuit, IC batteries, amplifier IC, logic IC, interface IC, equalizer IC, driver IC, and digital potentiometer IC.

6. What are the Advantages of IC Chips?

The advantages that you will realize by using the IC chips include:

- The size of the IC chips is extremely small in comparison to the size of discrete circuit chips.

- It also has an extremely small weight in comparison to the weight of discrete circuit chips.

- It consumes low power due to the small size and weight thus saving on power.

- You can easily replace an IC chip instead of going through the stress of repairing.

- It has a higher speed of operation since it does not have a capacitance or parasitic effect.

- It experiences very small temperature differences between the components of the circuit.

- You can use it for small signal operations.

7. Are there Disadvantages of IC Chips?

Yes, there are disadvantages of using the IC chips.

Some of the disadvantages of using the IC chips include:

- You cannot fabricate the indicators or the coils of the IC chips.

- IC chips can only be handled properly in a limited amount of power.

- You will experience a lot of problems in the assembly process of high grade P-N-P IC chips.

- Achieving low temperature co-efficiency using IC chips is difficult.

- It limits the dissipation of power to 10 watts.

- Obtaining high voltage operations as well as low noise is difficult.

- It is impossible to directly fabricate inductors.

- You will need additional components such as inductors and transformers while doing exterior connections.

8. What is IC Number?

An IC number is a simple process which you can use to identify the technical specifications and manufacturer of IC chips.

Every IC chip has a two-part serial number which signify different types of information.

The first part of the IC number usually denotes the information of the manufacturer.

The second part of the IC number will denote the technical specifications of the IC chip.

For instance, let us have a look at the IC number MC74HC00.

MC in the IC number will denote the manufacturer of the IC chip which in this case is Motorola.

74HC00 denotes the technical specifications of the IC chip that Motorola has manufactured.

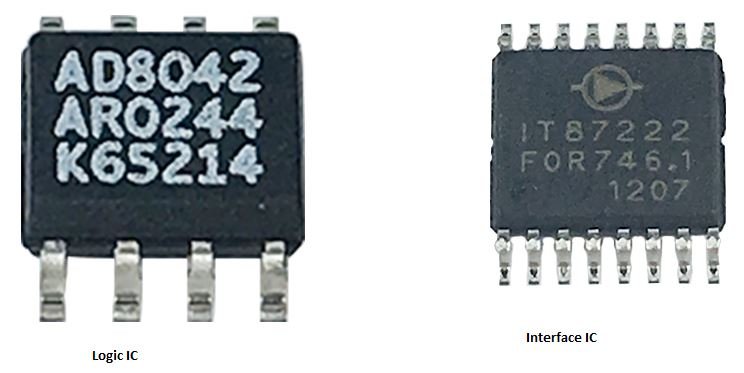

Figure Amplifier IC

9. How do you Find IC Chips Number?

You can find the IC chip number by reading the serial number from the top side of the integrated circuit.

You can identify the top side by looking at the face of the chip that faces you when chip stands on pins.

You may require the assistance of a magnifying glass to assist in identifying the IC number on the IC chips.

After that, you can search the IC number online to obtain a link to the data sheet about the IC chip.

10. What is Digital Integrated Circuit?

Digital integrated circuits are IC chips that you can use in handling discrete signals such as binary values of 0 and 1.

It depends on the identification of true or false logical operations.

They use digital logical gates, flip flops, as well as multiplexers among others.

These designs are economical and easy to design.

Modern digital integrated circuits depend on Boolean functions including, OR, AND, and NOT to build functionality.

Some of the digital integrated circuit chips include:

- Logic ICs

- Memory chips

- Power management ICs

- Interface ICs such as level shifters, serializers and deserializers.

- Programmable devices

11. How does IC Chips Work?

An IC chip consists of tiny capacitors, resistors, and transistors in thousands or millions fabricated on a semiconductor.

An IC chip depends on the components to perform different functions which end up doing multiple calculations and tasks.

The most important part of the IC chip is the transistor which assists in the normal function of the chip.

It has diodes which act as valves that allow the flow of current in one specific direction.

Apart from that, the IC chip also depends on the resistor to offer resistance to current.

The capacitors on the IC chi also assist in the storage of electric charge.

What’s more, it has inductors that store the energy in the form of an electric field in larger IC chips.

The microprocessor provides the IC chips with the memory that it requires to perform calculations and follow logic.

The logic or the protocol will provide the IC chips with the directions on how to process electricity as well as data.

You can refer to the microprocessor as the main operating system that controls the functions of the IC chip.

12. How does Linear IC compare to Digital IC?

Even though they have their differences, the Linear IC is the analog version of the digital IC.

Whenever you are using both, you will identify the following differences and similarities.

- You can identify the linear IC as an analog IC while the digital IC is the non-linear IC.

- Linear IC inputs and outputs take on continuous range of values with the outputs being proportional to inputs.

Digital ICs on the other hand have circuits whose voltage inputs and outputs are limited to low or high.

- You can use the linear IC on air crafts, vehicles, space ships, radars, oscilloscopes and PLL among others.

Digital ICs are important components in clocks, computers, digital watches and calculators among others.

- The design requirements of linear ICs are more drastic in comparison to digital integrated circuit chips.

- You can commercially find linear IC chips as operational amplifiers, voltage comparators, voltage multipliers, microwave amplifies and regulators among others.

Digital ICs are commercially available as memory chips, microprocessor chips, analog to digital chips or digital to analogue chips.

Additionally, you can commercially find the digital IC chips as counters, flip flops, logic gates and registers among others.

- Linear integrated circuit chips consist of fewer transistors in comparison to digital integrated circuit chips.

Intergrated Circuit

13. What is a Monolithic Integrated Circuit?

This is a complete circuit or group of circuits that are placed on a single piece of semiconductor or silicon.

It has a typical size of 1.25 mm square with 50 or more than 50 components such as resistors or transistors.

You can also identify it as a planar IC since it assumes the form of flat surfaces.

Integrating different types and large numbers of transistors on smaller chips increase the speed of functionality of the IC chip.

Apart from that, it is cheaper and smaller in magnitude in comparison to those on discreet electronic components.

14. What is a Thin Film IC?

This is a device that is larger than a monolithic IC chip but smaller than discrete units.

You can use a thin film IC when the power output is comparatively higher.

You can fabricate a thin film IC by depositing conducting material films on the surface of ceramic or glass bases.

At the same time, you can control the thickness and width of the film and use different materials with proper resistivity.

Capacitors of thin films are made by sandwiching insulating oxide films between two conductor films.

You can make an inductor by depositing spiral formation of films.

Diodes and transistors are produced through thin film technology with connections of tiny discrete components into the circuit.

15. What are the Characteristics of IC Chips?

The min characteristics of IC chips include:

· Material

IC chips consists of semi conducting materials such as silicon materials.

It involves mixing ultrapure silicon with precise and small amounts of elements that create different characteristics of electronic materials.

· Packaging

The IC chips are often too small and delicate for you to handle directly thus the availability of different packaging types.

You may find chips with dual inline packages (DIP) which are long rectangles with four or more pins on both sides.

· Size

The size of the IC chips will vary accordingly from 1 square mm to an excess of more than 200 square mm.

The package which contains that IC chips are often larger than the chip itself.

The thickness varies from fractions of a millimeter to a few millimeters.

· Density

The density of transistors on an IC chip varies and has been on the increase since by a double digit very two years.

As the density of the chip increases, the functionality of the same chip also increases.

· Integration

IC chips integrate different types of components on one chip so that they can perform one function.

Implying that the functions that depended on numerous chips are integrated into one smaller chip.

The process of integration is still being developed as time goes by leading to smaller and lighter devices.

· Power Supply Voltage

This is the maximum and minimum power supply voltage which includes:

- Maximum or minimum input power supply voltages

- Rated output voltage

- Source and sink current

- Temperature and environmental variations of the power supply voltages

· Design of the IC Chip

The design of the IC chip usually varies depending on the function of the IC chip.

You may have the standard design which is easily available and easy to make.

Apart from that, you may have the unique design of the IC chip which is more complex and take time to develop.

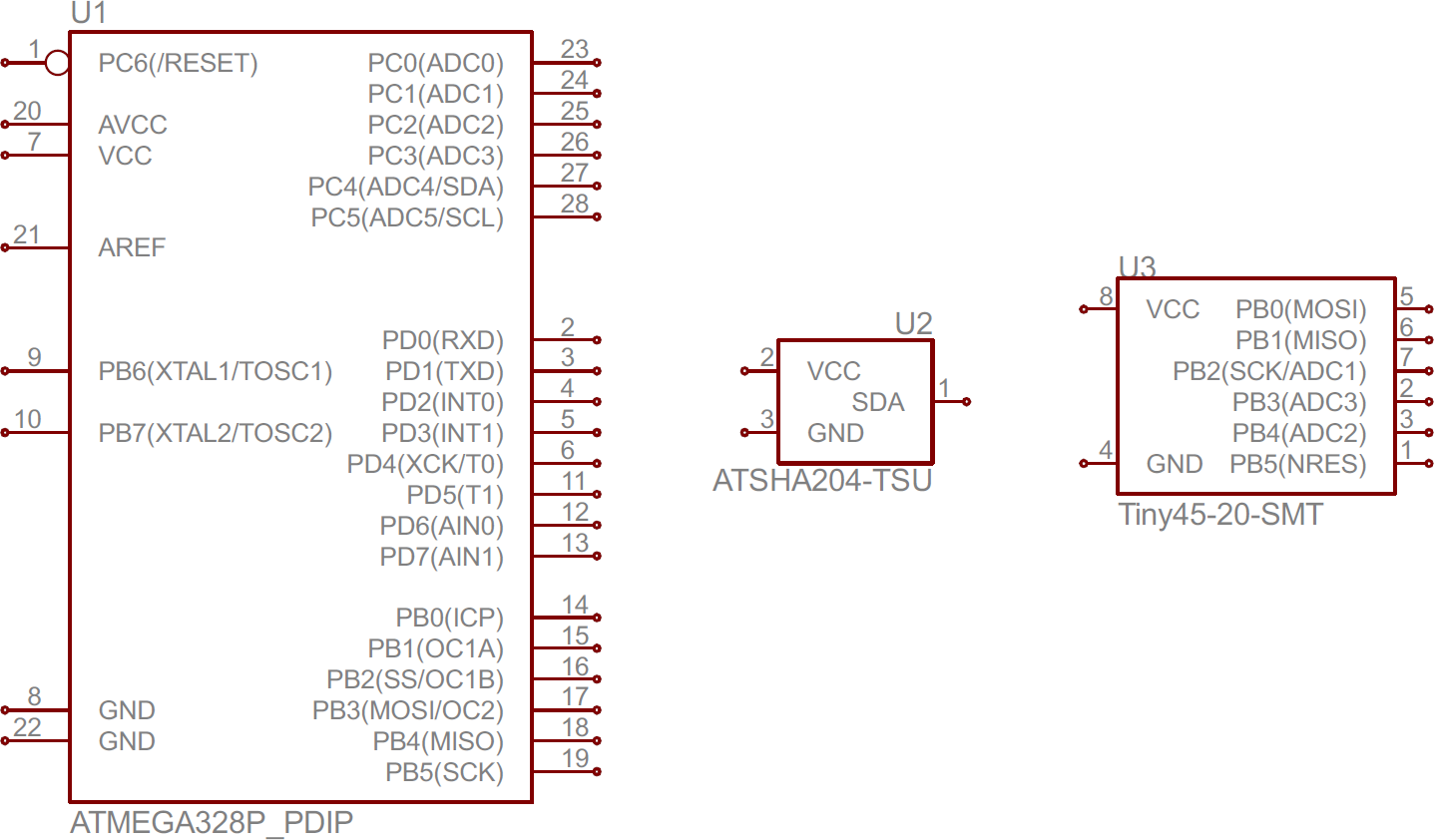

16. What is the Symbol of IC in Circuits?

Symbols of IC in circuits are smart connectors that assist in the presentation of IC chip schematics, blue prints and wiring diagrams.

You can change the symbols of IC in circuits in terms of appearance, color and style according to your requirements.

Every component on an IC chip has a symbol that will make it easy to identify during the designing and manufacturing process.

17. What is the difference between Monolithic and Hybrid IC?

The following are the main differences between the monolithic and hybrid integrated circuits:

IC Schematic – Photo courtesy: Spark Fun

- Monolithic IC chips are fabricated on a single chip while hybrid IC consists of integrating different individual chips.

- Monolithic IC have the full circuits on single silicon pieces with a package enclosure and connecting leads.

Hybrid ICs consists of one or more chips and are constructed using mixed technology including GaAs chips with silicon chips.

- Monolithic integrated circuit chips are smaller in size in comparison to the larger hybrid integrated circuit boards.

- The components of monolithic IC are often fused together through different methods such as ion implantation or diffusion.

Interconnections of hybrid integrated circuits are often established through transmission lines in TEM modes.

- Monolithic ICs are often more expensive in comparison to the less expensive hybrid ICs.

- Monolithic ICs are often less flexible in comparison to the great flexibility in hybrid IC chips.

18. What are IC Sockets?

An IC socket is a device that you can use to contain an integrated circuit chip.

You will use it as a place holder for IC chips to allow safe insertion and removal of the integrated circuit chips.

It protects the IC chips from any form of destruction especially during the soldering process.

19. How do you Identify IC Chips?

The process of identifying an IC chip may be confusing to you as there is no standard numbering system.

Manufacturers usually use a data sheet as well as identification numbers.

You will go through the following steps to identify an IC chip.

Figure 6 Intergrated circuit

Step 1: Identification of Manufacturer

You may find the company name inscribed on the chip but many manufacturers prefer using obscure symbols.

You may need a magnifying glass to assist you in reading the number as the inscription is often very small.

Step 2: Look Up the Number in the Manufacturers Printed Catalog

After identifying the number, you will use a reference document in a catalog from the retailer for reference.

You can as well use the number to find out the manufacturer and technical specifications by searching online.

To identify the obsolete part, the manufacturers often have the information on their websites or on printed catalogues.

The information is often broken down into the families that the chip belongs to as well as families of related parts.

Apart from that, the information has a drawing of the outline and how to configure it in a circuit board.

Step 3: Refine the Search on Electronic Retailers’ Catalogue

You may hit a snag in the process of searching for the information about the chip online.

This may be as a result of poor searching criteria where you might key in the entire IC number.

For instance, to identify a wider variety of parts of “74ACT32SCX” you can key in “74ACT32″ or “ACT32”.

The technical specifications on one piece of equipment can help you identify part numbers and their alternates.

20. What are Active Components in IC?

Active components in an IC chip rely on a particular source of energy and can inject enough power into a circuit.

Implying that active components control the flow of electric current in the IC chip.

Active components of an IC chip include amplifying components including triode vacuum tubes or valves, transistors and tunnel diodes.

21. Are IC Chips Active or Passive Components?

IC chips can either be active or passive because it has both active and passive components.

IC chips are categorized as being active components because they have the ability to control the flow of electricity.

They have different components that assist in controlling the flow of electric currents such as transistors, valves and diodes.

On the other hand, IC chips can be categorized as being passive because they have passive components.

The passive components available in an IC chip include resistors and capacitors.

Types of ICs

22. Who Invented IC Chips?

Jack Kilby is known as the inventor of the integrated circuits in 1958.

Robert Noyce invented the monolithic integrated circuit chip in 1959 after a series of attempts from other individuals.

It was invented at an electronic laboratory at Fairchild Semiconductors.

23. What is MOS Integrated Circuits?

MOS integrated circuits is a type of IC chip made out of Metal Oxide Semi-conductors based on the MOSFET structures.

The MOSFET structure often makes it possible to build MOS ICs with very high densities following a simple process.

MOS ICs are used on a wide variety of applications in the digital field of integrated circuit chips.

24. What is the Cost of Integrated Circuit Chips?

When it comes to calculating the cost of IC chips, you have to look at a number of different factors.

The silicon die used to be a very important factor as you could determine the cost by looking at the size.

Apart from silicon, there are other components that you need to consider that play equal and important roles.

These factors include the cost of package, test cost, die cost and shipping cost.

Final IC cost = package cost + test cost + die cost + shipping cost

25. How do you Package IC Chips?

Packaging the IC chips is the last step of the manufacturing process of IC chips.

You need to package the IC chips by encapsulation in supporting cases which prevent corrosion as well as physical damage.

The package should be able to support electrical contacts that connect the IC chip to a circuit board.

Apart from that, you need to have the following factors under consideration when designing a package:

· Electrical Conductivity

The material has to exhibit certain characteristics such as low capacitance, low resistance and low inductance.

The material and the structure of the package must prioritize signal transmission properties and minimize negative impact of parasitic elements.

· Mechanical and Thermal Factors

The package should exhibit the following mechanical and thermal properties:

- keep the IC chips from any form of potential damage such as physical breakage

- have an airtight condition that will keep away moisture

- Provide perfect heat dissipation properties to keep away excess heat from the chip

- Must exhibit proper means of connecting to the printed circuit board.

· Economic Factors

You should consider having the most effective package in terms of functionality at the most convenient cost.

You should opt for the least expensive materials in making the package of an IC chip.

There are different types of packaging materials that you can choose from including ceramic and plastic.

Apart from that, you may also decide on the packaging type that you need including:

- Through hole technology

- Chip carrier

- Surface-mount technology

- Flat package

- Pin grid array

- Small outline integrated circuit

- Ball grid array

- Multi-chip packages

- Chip scale package

- Transistor, diode, small pin count IC packages

26. How has IC Chips Technology Evolved since Invention?

Jack Kilby came up with the invention of the IC in 1958 and since then, many people have followed in improving it.

Six months after the invention of the IC, Robert Noyce came up with the idea of developing the monolithic IC chip.

This chip was easy to manufacture thus enabling the manufacturing of IC chips at a large scale.

It was used in making an Air Force computer as well as a pocket size calculator.

In the 1960s, the Moore’s law was put forward which has since been the mantra in the development of IC chips.

At the moment, you can find a state of the art chip with billions of components packed on a small semiconductor.

The IC chip which is the size of a human fingernail is much faster and more powerful in controlling modern devices.

New developments are also springing up as the quest of developing devices powered by light instead of electricity is underway.

This technology will lead to the development of faster and more powerful devices such as computers.

27. What are Mixed Integrated Circuits?

Mixed IC is a type of integrated circuit that uses both the digital circuits and analog circuits on one semiconductor die.

They have the capability of processing both digital and analog signals together.

For instance, an analog to digital converter is a type of mixed integrated circuit at work.

Mixed IC chips are available in many devices such as smart mobile phones.

It is the most cost-effective way of building modern consumer electronic devices.

28. How are the PIN Configurations for IC Chips?

All IC chips are polarized and every pin is unique in terms of the function and location.

Implying that an IC chip package has to have a particular way of conveying the different types of pins accordingly.

Most ICs use a dot or a notch that will indicate the proper location of the pin hence its function.

After identifying the location of the first pin, the other pin numbers usually increase sequentially as you move.

You will move counter clockwise around the chip as you name and number the pins accordingly.

29. How do you Specify Integrated Circuit Chips?

You can specify integrated circuit chips by looking at the following:

- Power requirements of the IC chips

- Density of the IC chip

- Size of the IC chip

- Design of the IC chip

- Integration of the IC chip

30. How do you Mount IC Chips?

IC

The main process that you will use in mounting IC chips soldering.

The process involves different styles including:

- Use of small conical tips

- Use of solder paste and reflow

- Drag soldering

In this guide, we will focus on drag soldering as the main process of mounting IC chips.

Step One: Preparation Stage

At this stage you will collect all the materials that you need such as solders, soldering station, flux, and clean wipes.

You will also clean all the equipment as the process does not require any form of contamination.

Step Two: Mounting Process

First, you will apply fresh amounts of fresh flux and then place the IC chip carefully on the board.

You should make sure that the pins line up as proper as they can be.

After that you can either tack a few pins or use high temperature adhesives to hold the IC chip in place.

Step Three: Soldering Process

You can start by tinning the tip after cleaning and filling the bevel with some solder.

The solder will glide over the pins, heating them, and depositing the right amount at the end of every pin.

The right amount of solder will deposit at the end of every pin due to the flux, temperature difference and surface tension.

It results in high quality fillets that require no solder wick as the right amount of solder deposits at every transition.

You have to be careful not to put too much solder that will overload the pocket.

Glide the pins gently with minimal pressure to allow the pins to mount properly on the board.

After that, you need to clean the area with clean water or alcohol to get rid of any impurities left.