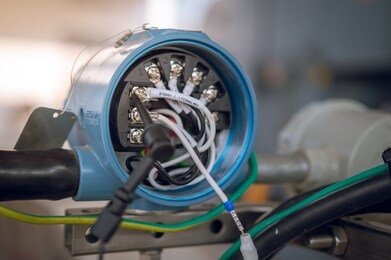

Temperature transmitters, or you can also call them temperature sensors, are electronic devices used to send a temperature measurement over two wires to the processing unit. They are essential for measuring temperature accurately in various applications. Temperature sensors can be widely used in industries such as manufacturing, automotive, aerospace, and even in our everyday appliances. Temperature transmitters help us monitor and control processes, ensuring that everything operates within safe temperature ranges.

The two commonly used devices, that apply temperature transmitters, are Resistance Temperature Detectors, which can be abbreviated as RTDs, and thermocouples. These sensors serve similar purposes but operate on different principles, have varying temperature ranges, accuracy, linearity, response time, vibration and shock resistance, cost, and offer distinct advantages. In this article, I will guide you through the key differences between RTDs and thermocouples, helping you choose the right one for your specific needs.

Resistance Temperature Detectors (RTDs)

RTDs operate on the principle that the electrical resistance of a material changes predictably with temperature. Typically, RTDs use materials like platinum, copper, or nickel as their sensing element. Here are the key characteristics of RTDs:

- Temperature Range: RTDs are suitable for a temperature range from -200°C to 600°C (-328°F to 1112°F). Some specialized RTDs can measure temperatures beyond this range.

- Accuracy: They offer higher accuracy and stability, often achieving ±0.1°C or better.

- Linearity: RTD temperature-resistance characteristics are highly linear, making them easy to calibrate and providing precise measurements.

- Response Time: RTDs generally have slower response times due to their higher thermal mass.

- Vibration and Shock Resistance: They are relatively fragile and sensitive to mechanical stress.

- Cost: RTDs are typically more expensive to manufacture and calibrate.

Thermocouples

Thermocouples, on the other hand, rely on the Seebeck effect, where a voltage is generated when two dissimilar metals are joined at one end. The magnitude of this voltage is proportional to the temperature difference between the hot junction (measuring point) and the cold junction (reference point). Here are the key characteristics of thermocouples:

- Temperature Range: Thermocouples cover a broader temperature spectrum, spanning from -270°C to 2,300°C (-454°F to 4,172°F).

- Accuracy: They offer lower inherent accuracy, typically ±1°C to ±2°C.

- Linearity: Thermocouples have nonlinear voltage-temperature characteristics, which can complicate calibration and data interpretation.

- Response Time: Thermocouples have faster response times and are ideal for applications where quick temperature changes need to be monitored.

- Vibration and Shock Resistance: They are robust and can withstand vibration and shock, making them suitable for industrial and automotive applications.

- Cost: Thermocouples are cost-effective and widely used in applications where high accuracy is not critical.

Which One to Choose?

The choice between RTDs and thermocouples depends on your specific requirements. If you need high accuracy, stability, and precise measurements within a relatively narrow temperature range, RTDs are the way to go. They are perfect for laboratory settings and industries where precision is paramount.

On the other hand, if you're dealing with extreme temperatures, require fast response times, or need a durable and cost-effective solution, thermocouples are the better choice. They are widely used in industrial processes, automotive applications, and any scenario where ruggedness and a wide temperature range are essential.

Both RTDs and thermocouples have their unique advantages and are suitable for various applications. It's essential to consider your specific needs and the environment in which these sensors will be used when making your selection. Regardless of your choice, these temperature transmitters play a crucial role in ensuring safety and efficiency across a wide range of industries.

Now that you've gained a better understanding of the differences between RTDs and thermocouples, you're better equipped to make an informed decision for your temperature measurement needs. If you are looking for a temperature transmitter, don’t hesitate to contact us!